EyeC Quality Link

The EyeC Quality Link connects your press and rewinder for total quality control at maximum productivity.

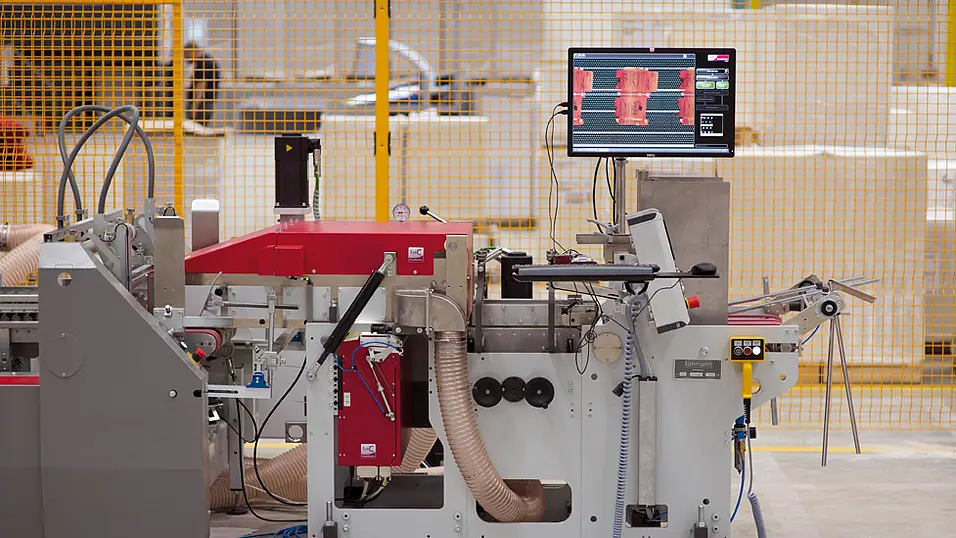

In-line inspection systems

Top quality right from the printing process – 100% control on your printing press or your finishing machine.

Our EyeC ProofRunner line increases your efficiency and sustainability.

Finally there is an easy way to check all of your prints against a approved sample! With an EyeC ProofRunner you get automatic 100% inspection of all items, content verification against your sample as well as the best mix-up prevention you can imagine – right on the printing press or on a rewinder or seamer.

The process is simple and yields accurate results; so you can rest assured that you will print exactly what your customer expects. Inspection results are instantly available and can be used for immediate corrective action.

And with our AI option you can easily distinguish relevant from non-relevant errors. This gives you the means to completely control and monitor your printing process, and ensure absolute quality from a tiny label to a luxury packaging.

Ensure your print quality and keep your customers satisfied.

Meet any quality requirement while avoiding waste, and saving machine and work time.

Our EyeC ProofRunner Highlight series is perfect for luxury packaging inspection.

Always see how many good items you have printed - no overproduction necessary.

Whether you want to print sheets or on flexible materials, produce labels or check cartons on your folder gluer. We have a solution for you.

Keeps track of inspection results and certifies quality.

The EyeC Quality Link connects your press and rewinder for total quality control at maximum productivity.

High-resolution and extremely fast and user-friendly web in-line inspection system for reel to reel and reel to sheet solutions.

A retrofit module designed for 100% print inspection of sheets during printing.

Creates the ultimate folding carton inspection solution and is a cost-effective and reliable solution.

Thank you for your interest in EyeC.

We’ll get back to you as soon as possible.

Callback-Request

Thank you for your interest in EyeC.

We’ll get back to you as soon as possible.